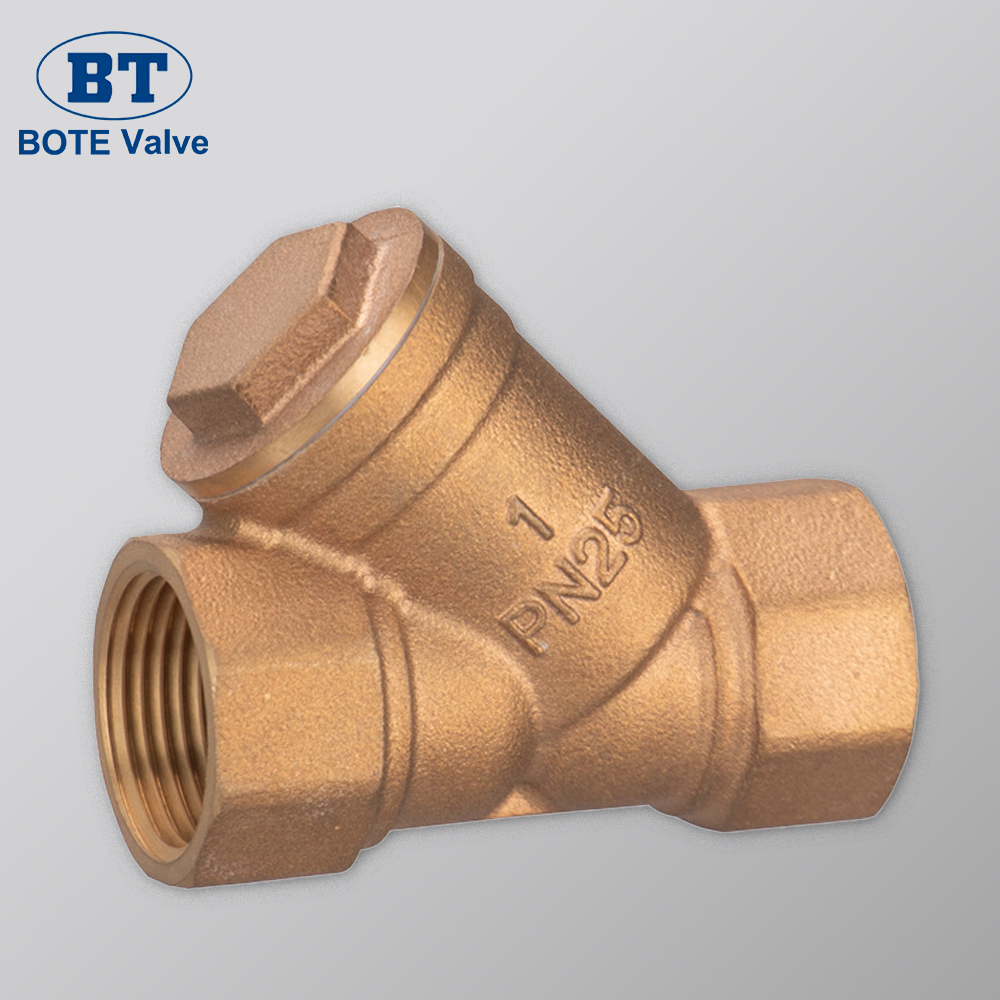

The Y shaped strainer gets its name from how it works, directing fluids through an angled chamber between 45 to 60 degrees where there's a filtration screen inside. The way this thing is built actually helps create good balance in pressure differences across the system. What happens is that debris collects down in what we call the 'leg' part of the strainer but doesn't really slow down the flow much. These strainers take up way less space compared to their basket counterparts, usually around 30 to 50 percent smaller which makes them great when installation room is limited. Plus, they come with reinforced construction that can stand up to serious pressure demands, handling up to 6,000 pounds per square inch in those tough oil and gas environments where reliability matters most.

Mesh sizes typically range from 100 to 5,000 microns, with finer screens (100–500 microns) used in chemical processing and coarser variants (1,000+ microns) in steam systems. A 2023 fluid dynamics study found that oversizing mesh openings by just 15% can increase pump wear by 22%, underscoring the importance of precise particle retention.

Modern Y strainers increasingly use duplex stainless steels and nickel-aluminum bronzes, which offer 40% greater corrosion resistance than standard 304 stainless steel in saline environments. Advanced casting techniques eliminate weak seams, enhancing reliability in high-vibration settings, while ceramic-coated screens are emerging in abrasive slurry applications.

Y strainers act as first line defense in those really harsh environments where all sorts of junk needs stopping before it gets into pumps or valves. They catch stuff like rust bits, leftover weld slag, and mineral buildup that would otherwise cause serious problems down the line. For oil and gas applications, these Y shaped filters can take on some serious pressure levels around 6,000 psi according to ASME standards from 2021. The design works well for removing larger particles from both crude oil and natural gas streams. Over in chemical processing facilities, operators often go with special alloys such as Hastelloy C-276 when dealing with corrosive materials. These materials help prevent valve failures caused by tiny particles getting stuck inside during those long running production cycles that never seem to stop.

Y strainers work pretty well at catching sediment and scale buildup in those chilled water loops, which keeps the heat transfer running smoothly in most commercial HVAC setups. What makes them stand out is how easy they are to install vertically in tight mechanical spaces. This vertical installation actually cuts down on pressure loss somewhere around 15 to maybe even 20 percent when compared against traditional basket strainers used in similar steam systems. Many facilities that switch to 40 mesh stainless steel screens notice something interesting too. They end up cleaning coils in their air handling units about 30% less often because these screens grab bigger particles, anything over 500 microns really, before they can clog things up.

Water treatment plants typically install Y strainers featuring 316L stainless steel mesh to filter out sand particles and organic debris from incoming water lines, meeting the NSF\/ANSI 61 requirements for safe drinking water applications. When it comes to food and drink manufacturing, companies look for cleaning-in-place compatible models with smooth surface finishes around 0.8 microns roughness average to keep bacteria at bay. The duplex system setup means continuous operation is possible even when running complex processes such as making yogurt or brewing beer where downtime would be costly. According to recent market data from 2023, nearly all beverage makers reported getting almost completely clear products after switching to these twin chamber Y strainers, with about 92 percent seeing their batches free from contaminants down to 99.9% purity levels.

Y strainers act as guards for important parts by catching debris before it gets into delicate machinery. The special angle of these filters sends particles down into a trap area while keeping the fluid moving smoothly through the system. We've seen pressure drops cut nearly half when using Y strainers instead of standard T-shaped ones. What this means in practice is that pumps don't get damaged from gritty material, valves stay clear, and those expensive flow measuring devices aren't constantly getting dirty readings. When picking out mesh sizes for most factory work, people usually go between 10 and 100 microns. Getting this right balances good protection against stuff getting through with making sure the fluid still flows at acceptable rates throughout the plant.

A chemical processing plant reduced quarterly pump overhauls by 35% after installing dual Y strainers in parallel. This setup enabled continuous operation during cleaning cycles and captured 92% of catalyst particles larger than 80 microns. Over 18 months, the facility avoided $217,000 in unplanned downtime and replacement costs, according to maintenance records.

Optimal placement balances hydraulic performance with accessibility. Best practices include installing strainers:

Integrating Y strainers with pressure transducers and IoT-enabled differential pressure sensors allows real-time monitoring. Alerts trigger when blockage exceeds 15%—a threshold linked to 99% system availability in water treatment operations (2023 Process Optimization Report). When connected to CMMS platforms, these systems automate maintenance scheduling and cut manual inspection labor by 50%.

Y strainers support both horizontal and vertical installation, adapting to complex layouts with minimal space requirements. Their compact profile allows direct integration without rerouting pipes. Vertical setups are especially useful in multi-level facilities, minimizing structural supports while maintaining performance in high-pressure systems up to 6,000 psi.

Regular inspection—every 3–6 months depending on particulate load—ensures long-term effectiveness. Blow-off valves enable rapid debris removal without system shutdowns, a key advantage in continuous processes like chemical manufacturing. Removable screens simplify cleaning and help maintain ASME BPE compliance in hygienic applications.

Getting equipment positioned right makes all the difference for both safety during maintenance work and how smoothly things run day to day. The access points need to follow those OSHA guidelines from section 1910.147 regarding lockout/tagout procedures. Recent improvements in how flanges and gaskets are made have cut down on leaks quite a bit actually around 42 percent fewer incidents in places where machines vibrate a lot. This means components last longer and replacements happen less often. Throw Y strainers into the mix when planning regular maintenance checks and factories see about 31% less unexpected shutdown time than companies relying solely on fixing problems after they occur. Makes sense really since catching issues early saves everyone headaches later on.

Y strainers operating above 300 PSI must meet ASME B16.34 for pressure containment and API 594 for flanged connections. Dual-certified 316/316L stainless steel is used in 72% of high-pressure installations, offering superior corrosion resistance and 20% higher yield strength than 304 stainless steel.

| Pressure Rating | Material Compatibility | ASME Certification Requirement |

|---|---|---|

| ≤ 1500 PSI | 316 Stainless Steel | B16.34 Class 150 |

| 1500–2500 PSI | Duplex Stainless | B16.34 Class 300 + NACE MR0175 |

| ≥ 2500 PSI | Inconel 625 | B16.34 Class 600 + HIC Testing |

An offshore platform in the North Sea operated for 11,000 hours without valve failure after upgrading to wedge-wire screen Y strainers rated for 3600 PSI. The 3-mm thick Hastelloy C-276 bodies achieved 98% particulate capture efficiency while resisting hydrogen sulfide concentrations over 250 ppm.

Biannual hydrostatic testing at 1.5 times the maximum working pressure helps detect stress corrosion in high-pressure alloys. Operators following API 570 inspection guidelines report 43% fewer emergency shutdowns (Process Safety Quarterly 2023), confirming the role of proactive verification in system reliability.

Hot News

Hot News2025-07-08

2025-07-03

2025-07-02

2025-12-08