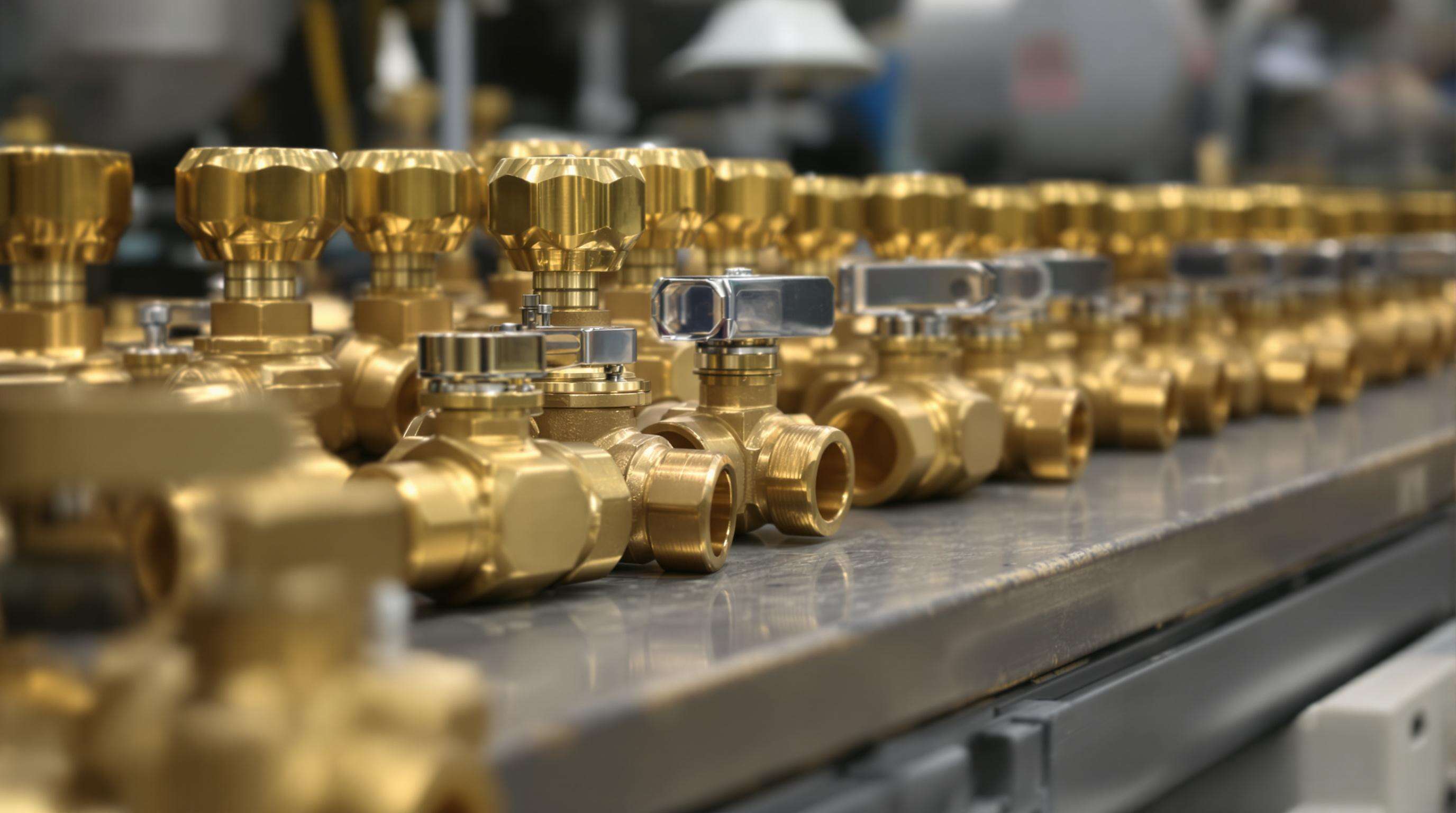

Brass ball valves play a key role in making plumbing systems more sustainable because they resist corrosion while being built with precise engineering. These valves have what's called a full-bore design which basically means there's less restriction when water flows through them. This actually cuts down on energy needed for water distribution systems by around 18 percent according to recent studies from Fluid Systems Analysis back in 2023. What makes these valves stand out is how long they last. Brass alloys tend to hold up really well over time, often lasting more than 25 years before needing replacement. That longevity means fewer parts ending up in landfills and saves money on constant repairs and replacements for building managers and homeowners alike.

Green practices have become really important in the plumbing world lately. A recent industry check found that around two thirds of plumbers are going for valves constructed from materials that can be recycled easily and don't harm the environment much. Brass ball valves fit the bill pretty well since they can be recycled at about 92 percent efficiency rate. Plus, these valves work great when installed alongside solar water heating systems and those graywater recycling setups many buildings are adopting nowadays. What makes brass ball valves stand out even more is their compliance with lead-free standards, which helps projects earn points toward green certifications such as LEED ratings. Because of this, we see them showing up regularly in both homes and businesses where owners care about reducing their environmental footprint.

The EPA has set strict rules for lead content in drinking water parts, specifically under NSF/ANSI 61 standards, which demand levels stay under 0.25%. To comply with these regulations, many manufacturers started using silicon based brass instead of traditional materials. This new alloy meets all the no lead requirements but still holds up well against pressure changes and heat exposure. Looking at recent data from city water quality checks, there's been about a 40 percent drop in problems related to lead contamination in plumbing systems since around 2019. Municipal inspectors across several major cities report fewer incidents when they check pipes and fixtures now compared to just a few years ago.

More cities are turning to brass ball valves these days because they just plain work better under pressure situations. According to some recent market research from last year, demand for brass valves is expected to grow at around 7 percent each year until 2030. This trend makes sense when looking at all the smart city projects popping up everywhere plus those new developments along coastlines designed to withstand flooding. Brass valves last much longer than their plastic counterparts too. Maintenance crews report about thirty percent savings on replacement costs over time, which explains why many forward thinking municipalities are incorporating them into long term plans for greener infrastructure solutions.

The new Reduction of Lead in Drinking Water Act requires plumbing parts to have less than 0.25% lead content, which is making companies switch to brass ball valves that meet these standards. Most cities across America, about 87%, are now asking for NSF/ANSI 372 certification when installing public water systems. If they don't follow these rules, there can be serious fines running over $15,000 for each problem found. Because of these strict requirements, manufacturers are having to come up with new ways to make their alloys while still keeping the same level of quality and durability that customers expect from their products.

New alloy blends like eZeebrass are changing the game in metal manufacturing. Made mostly from copper (around 58%) plus some silicon and magnesium, this material meets strict zero-lead standards without sacrificing strength or longevity. Tests conducted recently found that these advanced metals can handle well over 10,000 pressure cycles even when exposed to chlorine, which makes them about 35% more resistant to corrosion compared to regular brass according to findings published in Material Innovation Report last year. Another big plus is how much easier they are to machine during production processes. Factories report cutting down on scrap material by roughly 18%, which helps manufacturers stay compliant with regulations while at the same time reducing their environmental impact significantly.

Leading manufacturers utilize closed-loop recycling systems that recover 92% of brass scrap during machining. Energy-efficient induction melting furnaces reduce CO emissions by 40% compared to conventional methods, aligning with ISO 50001 energy management standards. Water-based lubricants are now standard in threading operations, eliminating hydrocarbon contamination risks in potable water applications.

Engineers evaluate alloys based on three key criteria: mechanical strength (â 50 ksi yield strength), lifetime cost (â$0.12/year per valve), and recycled content (â 65% post-industrial scrap). Bimetal designs featuring stainless steel cores and brass shells offer 20-year service lives in harsh coastal environments, reducing replacement frequency by 60% compared to all-brass variants.

The latest brass ball valves come with specially designed low friction features that really cut down on pressure losses throughout plumbing systems. According to a recent study on plumbing efficiency from 2025, these improved designs actually save around 8 percent in pumping energy costs for commercial buildings, while municipal water networks see savings closer to 12 percent. This kind of efficiency helps building managers meet requirements set out in the ASHRAE Standard 90.1-2023 document, which is becoming increasingly important for anyone looking to get their HVAC systems certified under the ENERGY STAR program. The numbers might seem small at first glance, but over time they add up to real money saved and better performance overall.

Most brass ball valves can go decades without leaking, often lasting around 25 years or more before needing replacement. That's roughly three times longer than what we see from standard plastic valves on the market today. When it comes to waste, brass really shines. Studies looking at their entire life cycle indicate these valves produce about two thirds less material waste compared to PVC systems when measured over a 30 year period. As for upkeep, brass valves require practically no attention. Industry data suggests they need only about 0.2 hours of maintenance work each year, while stainless steel valves demand nearly 1.5 hours of service time under comparable operating conditions.

| Metric | Brass Ball Valves | PVC Valves | Stainless Steel Valves |

|---|---|---|---|

| Average Lifespan | 25-40 years | 8-15 years | 20-30 years |

| Recyclability Rate | 92% | 28% | 88% |

| Embodied Carbon (kg CO2e/unit) | 15.2 | 9.1 | 22.8 |

| Maintenance Frequency | 10-year intervals | Annual | 5-year intervals |

Brass ball valves offer the most balanced lifecycle profile, delivering 83% lower lifecycle costs than stainless steel in potable water systems while avoiding the environmental persistence issues associated with plastics. With 100% recyclability and 74% of new valves incorporating post-consumer recycled content as of 2024, brass supports closed-loop manufacturing and circular economy principles.

Today's brass ball valves come equipped with smart actuators that link right into building automation systems. The way these work is pretty cool actually – they tweak water flow according to live occupancy info picked up by those little IoT sensors around the place. Studies show this setup can cut down energy consumption anywhere between 15% and maybe even 25% when used for heating, ventilation and air conditioning stuff. Brass bodies are naturally resistant to corrosion so they last forever basically. And because of how accurately these valves report their position back to the system, plumbers get much better control over water flow in all those fancy automated networks throughout buildings.

Brass ball valves with built-in sensors keep track of things like flow rate, pressure levels, and how tight the seals are, then send all this info to central monitoring systems. Facilities can spot small problems early on thanks to this setup, so they fix minor leaks before they turn into bigger headaches. Research from various industrial sites indicates that these smart valves last about 30 to maybe even 40 percent longer than regular ones. And think about all the water saved too millions of gallons stay in the pipes each year instead of dripping away unnoticed when something goes wrong.

A LEED Platinum office complex achieved 92% water efficiency using networked brass ball valves to regulate irrigation and cooling tower systems. The valves lead-free construction met strict environmental standards, while automated pressure adjustments prevented pipe stress during peak demand. Cloud-based diagnostics reduced inspection labor by 60%, streamlining maintenance operations.

The latest brass ball valves coming out soon have built-in smart chips that actually read how they're wearing down and track what's happening with fluids as it goes along. Some early prototypes already know when minerals start building up inside and change their settings on their own so water keeps flowing smoothly without anyone needing to fix them manually. Cities across the country are trying these smart valve systems right now. They use computer learning techniques to keep water pressure consistent throughout whole neighborhoods. One pilot program in Chicago saw energy savings around 20% just from better pressure management alone.

Brass ball valves play a key role in modern smart water systems, allowing for accurate control of water flow thanks to IoT monitoring tech. Cities working on their smart city projects tend to go for these valves because they work well with automatic pressure controls and leak detection systems that can cut down on wasted water losses by around 15-20% when compared to older methods. Government funding programs such as the Water Infrastructure Finance and Innovation Act (WIFIA) have definitely sped things up, and looking at recent procurement numbers from 2023 shows brass valves now make up about two thirds of all new installs in city water networks across the country.

Brass ball valves actually help buildings get those coveted green certifications because they're free from lead and can be completely recycled at the end of their life. The fact that these valves resist corrosion means they work really well in systems like geothermal heating and graywater recycling setups. We've seen data showing around a 40 percent drop in needing to replace materials when compared to plastic options. For places prone to earthquakes, the solid build quality of brass valves stands up against pressure spikes reaching as high as 1,000 pounds per square inch. This kind of durability helps prevent major system failures during tremors, which is obviously super important for safety reasons in regions where quakes are common.

Brass alloys resistant to dezincification work well in those coastal areas where humidity stays above 85% most days and there's constant salt spray in the air. Tests done under accelerated conditions indicate these special brasses last about three times longer than regular brass when exposed to marine conditions. They actually beat stainless steel too when looking at what it costs versus how long they last. Many coastal smart cities have started making DZR brass ball valves standard equipment for important infrastructure projects lately. We see them installed in storm surge protection systems and at the intake points of desalination plants where reliability matters most.

Brass ball valves are plumbing components that allow for the precise control of water flow. They are significant in sustainable plumbing systems because they resist corrosion, have a full-bore design for reduced energy use, and support long-term durability, reducing landfill waste and improving cost efficiency.

Brass ball valves contribute to environmental sustainability by being recyclable at a high efficiency rate, complying with lead-free standards, reducing waste with extended service life, and integrating with solar and graywater systems.

Brass ball valves need to meet strict EPA standards, particularly the NSF/ANSI 61 and 372 certifications, which require plumbing parts to have a lead content of less than 0.25%. Manufacturers are increasingly using lead-free, silicon-based brass alloys to meet these requirements.

They improve energy efficiency through low-friction designs that reduce pressure losses, leading to significant energy savings, meeting ASHRAE and ENERGY STAR standards, and integrating with building automation systems for optimized water flow.

Hot News

Hot News2025-07-08

2025-07-03

2025-07-02

2025-12-08