Gas valves these days act as safety backups in home systems, shutting off gas flow when something goes wrong like a sudden drop in pressure or unexpected temperature changes. The brass parts inside these valves are really important because they don't corrode easily, which means they keep forming good seals even after years of use. Some tests on materials show that quality brass valves cut down on leaks around 92 percent better than old fashioned cast iron ones. What makes these valves so useful is their quarter turn shut off feature. Just a quick twist stops gas from flowing through the pipes during emergencies, which is why plumbers always recommend installing them for fast response times when problems occur.

Modern gas valves actually have two main safety features working together mechanical pressure relief vents and those automatic shutoff sensors we all rely on. The system works like this when pressure inside goes over the safe limit by even half a pound per square inch, special springs pop open to let out extra gas at the same time solenoid valves shut down the flow completely. This setup stops pipes from bursting and cuts down on dangerous explosions. We saw how important this was during last winter's big freeze in Texas. Those safety mechanisms probably stopped around seventeen thousand possible gas leaks as they kept things stable despite wild pressure swings in older pipelines throughout the state.

In July 2022, a house in Denver exploded because a brass ball valve had corroded and stopped sealing properly. The valve let propane build up inside for around eight hours before it all went wrong. It turned out this particular valve had been installed back in 2010 and nobody had ever checked it since then. That goes against what NFPA 54 actually recommends which is checking these things every two years at minimum. While the blast did cause quite a bit of damage totaling about $2.3 million dollars worth, thankfully there were no people hurt thanks to those early warning systems kicking in when they should have. What happened here really shows why following basic maintenance schedules matters so much for keeping everyone safe from preventable accidents like this one.

The adoption of pressure-sensing and thermal shutoff valves has contributed to a 57% decline in gas explosions since 2018, according to the NFPA 2023 Report. Over 89% of U.S. states now require thermal shutoff valves in new constructions—a policy linked to a 34% reduction in gas-leak-related fires between 2020 and 2023.

When there's a fire or structural problem, emergency shut off valves kick in pretty fast, usually between two to four seconds, to cut off gas flow before it can feed the flames. These valves actually manage to stop gas from spreading in about 89 out of 100 fire situations by shutting down supply lines that are damaged. The ones that have UL listings typically rely on either motion sensors or detect changes in pressure differences when responding to dangers such as earthquakes shaking buildings or cars crashing into pipelines. According to reports from local fire services, houses fitted with working emergency valves see firefighters containing blazes around 40 percent quicker than those without them. That kind of response time makes all the difference in protecting property and saving lives during emergencies.

Automatic valves eliminate human delay, initiating shutdowns 78% faster than manual alternatives (Gas Safety International 2022). Key differences include:

| Feature | Automatic Valves | Manual Valves |

|---|---|---|

| Response Time | 2–5 seconds | 30+ seconds |

| Activation Method | Sensor-driven | Human intervention |

| Fail-Safe Mechanism | Pneumatic actuator systems | None |

While automatic systems carry a 35% higher initial cost, they prevent an average of $14,000 in incident damages (Home Safety Council 2023), offering long-term savings and enhanced protection.

Today's shut off valves work alongside gas detectors that automatically shut things down when methane levels hit around 5% of what could potentially explode. According to those ANSI Z21.78 guidelines most folks probably haven't read cover to cover, these modern systems can talk to smart alarm devices too. That means alerts get sent straight to phones of people living there as well as the local gas company. When these safety systems link into existing smart home networks, response times during emergencies drop dramatically. Some research from last year showed a reduction of about two thirds in how long it takes for help to arrive after detecting a leak. This not only stops problems before they start but also makes sure everyone involved knows exactly what's happening when something goes wrong.

When installed incorrectly, even the best valve tech won't perform properly. According to recent industry reports from Plant Engineering in 2025, around 38 percent of early failures in home systems come down to valves that aren't seated right. The usual mistakes include things like crooked threads, fittings that are too tight, and not enough sealing material between parts. These small problems create tiny leaks that build up over time and can become really dangerous. Looking at numbers from the National Fire Protection Association, these kinds of installation errors were behind about 17% of all gas related accidents last year. That's pretty significant when we think about safety concerns in residential areas.

| Maintenance Activity | Frequency | Critical Components Checked |

|---------------------------|---------------------|-------------------------------|

| Visual inspection | Monthly | Valve body, handle alignment |

| Operational test | Quarterly | Shut-off mechanism, stem movement |

| Professional inspection | Annually | Internal seals, pressure calibration |

Guidelines from leading industrial associations recommend this tiered approach, emphasizing annual professional evaluations to detect internal degradation invisible to untrained users.

Most homeowners stick to simple maintenance jobs like greasing handles, yet statistics show something alarming: according to the International Code Council report from 2024, around 92% of insurance claims related to gas valves come from people trying to install them without proper credentials. When trained pros tackle these jobs, they bring out special equipment for things like adjusting torque settings and checking pressures. This helps prevent serious issues down the road such as threads getting crossed during connection, actuators that aren't aligned properly, or pipes left hanging unsupported which eventually crack under stress. About 41 states across America now have laws requiring licensed experts for replacing gas valves. These regulations highlight just how important exact measurements and correct installation techniques are when it comes to keeping everyone safe and meeting building codes.

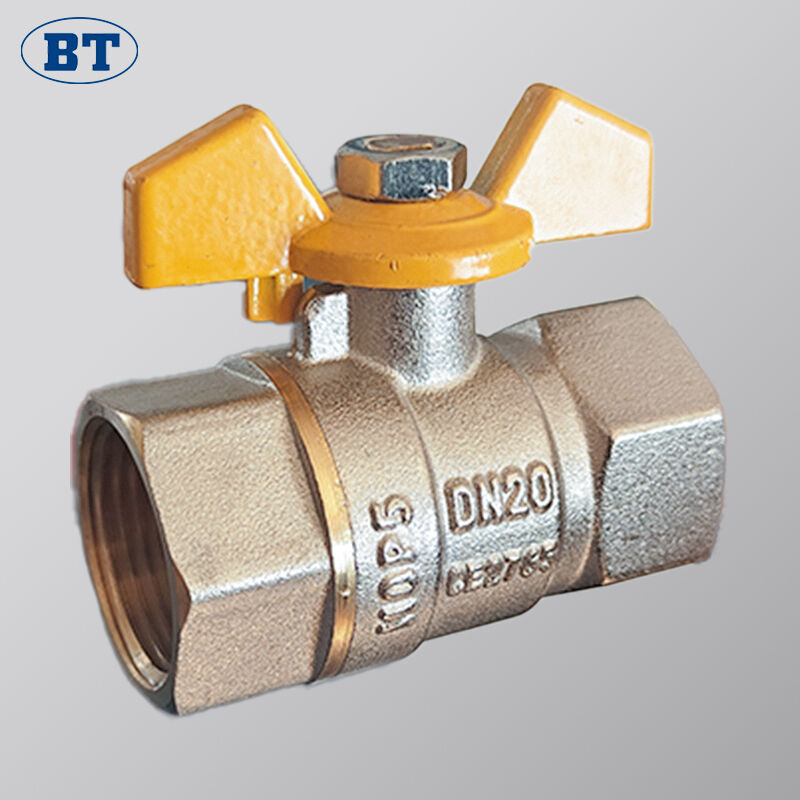

Most homes with gas lines rely on three main types of valves to manage flow and stop leaks. Ball valves are great because they shut off completely in just a quarter turn, which makes them perfect during emergencies when every second counts. Then there's gate valves that work differently - they have this stem that moves straight up and down to either let all the gas through or block it entirely. These tend to be installed where people don't need to adjust things often. The third option is solenoid valves, which connect to automated systems. When gas detectors pick up something wrong or those smart sensors get triggered, these valves will automatically cut off the supply. Pretty handy stuff for keeping everyone safe without having to run around flipping switches manually all the time.

| Valve Type | Key Safety Advantage | Operational Limitation |

|---|---|---|

| Ball | Leak-proof seal in closed position | Limited flow control precision |

| Gate | Zero flow restriction when open | Slow actuation speed |

| Solenoid | Instant automated response | Dependent on electrical systems |

Ball valves prevent 92% of manual shutoff errors in residential settings, reinforcing their role as the preferred choice for emergency isolation.

How valves work really matters when it comes to both safety and how easy they are to use in practice. Take those quarter turn valves, such as ball valves, which can be closed with just one quick motion. This feature becomes super important during emergencies when every second counts. On the other hand, multi turn gate valves need about three to five complete turns to operate properly, making them great for situations where precise control over the flow is needed, especially during routine maintenance tasks. The latest UL standards actually require these quarter turn valves to be installed no more than six feet away from gas appliances, ensuring people can get to them fast if something goes wrong.

Both the National Fire Protection Association (NFPA) and the American National Standards Institute (ANSI) set pretty strict rules about what materials should be used for gas valves, where they need to go, and how they must be tested. According to NFPA 54, any valves near gas meters within about six feet have to resist corrosion. Meanwhile, ANSI Z223.1 says that after installation is complete, there needs to be some kind of leak test done. Looking at data from 2023 regarding these fuel gas standards shows something interesting: homes that follow all the codes tend to have around 62 percent less gas leaks compared to those that don't meet the standards. That makes sense when thinking about safety concerns related to gas systems.

Fire safety studies show that when homeowners can easily access their main gas shutoff valves, emergency crews respond up to 40% faster during incidents. The International Fuel Gas Code actually specifies these requirements in section 404.11 they need to be free from blockage, properly marked, and placed right at the regulator exit points. Most building inspectors see this issue all the time. About 8 out of 10 professionals report finding valves tucked away behind stoves or water heaters as the number one problem during inspections. This continues to be a major concern for home safety experts who emphasize that quick access could literally save lives in critical situations.

Less than a third of homeowners actually know how to shut off their gas supply according to recent research from 2024 on household safety training. Cities that implemented programs pairing QR code maps showing valve locations with actual practice sessions saw a dramatic jump in preparedness rates among residents participating in these pilot projects. Some towns reported over 70% better emergency response capabilities after implementing such initiatives. The plumbing industry is pushing hard for all homebuyers to receive proper training when they sign the final paperwork at closing. After all, knowing where those critical valves are located could literally save lives during emergencies.

Hot News

Hot News2025-07-08

2025-07-03

2025-07-02

2025-12-08