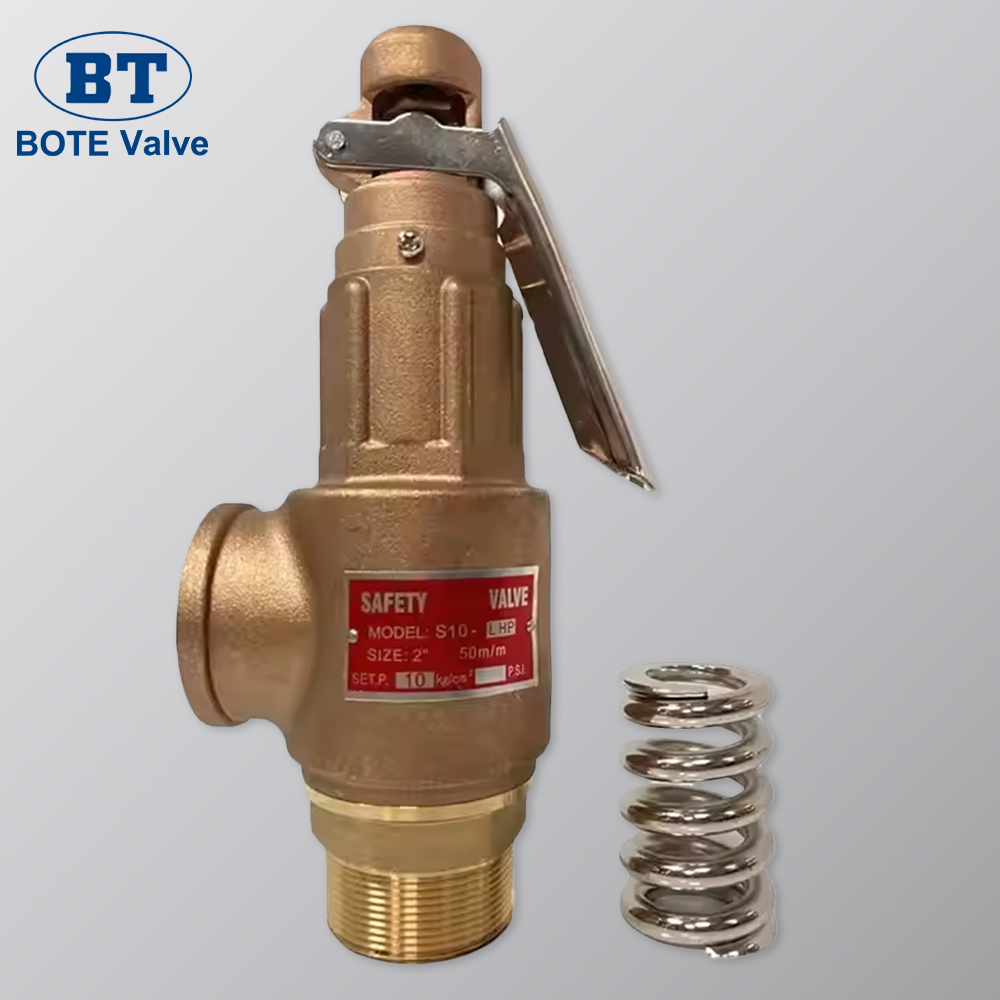

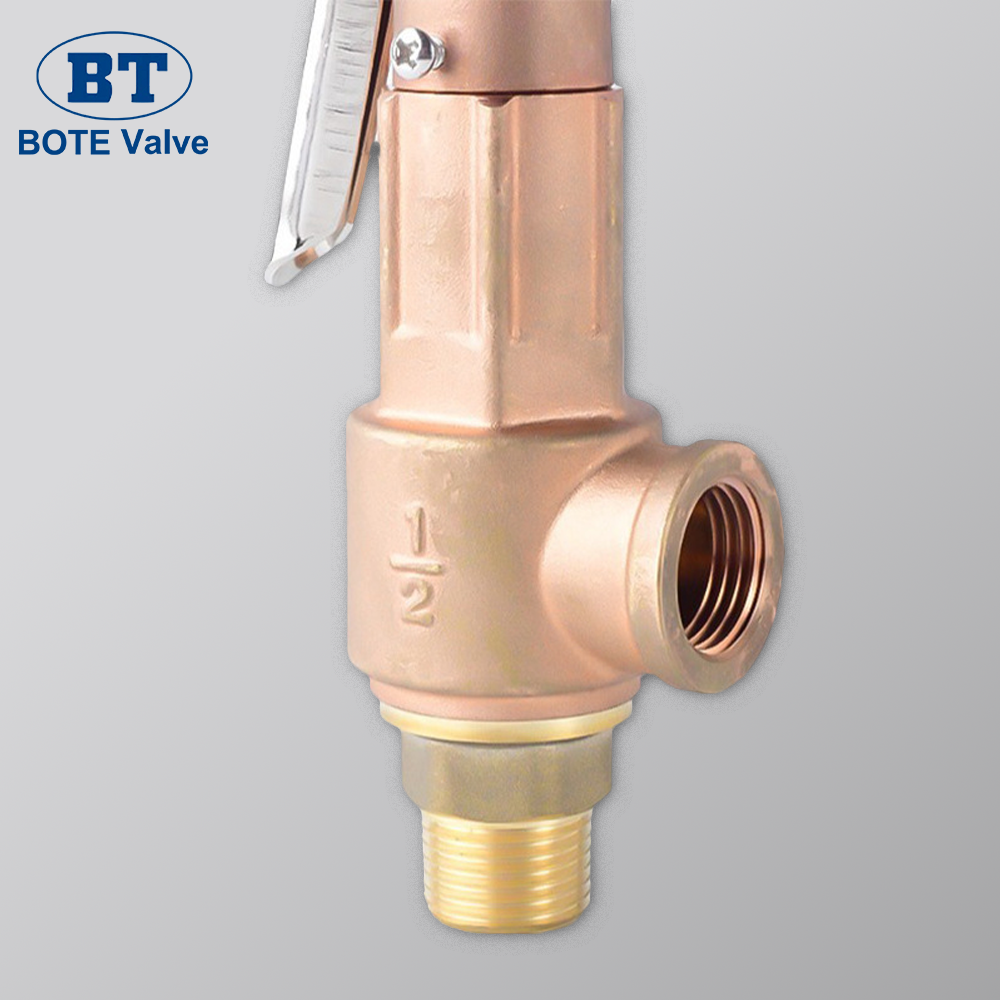

Manual Brass Boiler Safety Relief Valve - 1/2" to 2" Threaded Pressure Relief Valve

This manual brass boiler safety relief valve is engineered to prevent boiler overpressure, a critical safety hazard for industrial and commercial boiler systems. Crafted from high-strength forged brass, it resists high temperatures and corrosion, while the manual adjustment design allows precise control of pressure release values. Available in 1/2" to 2" threaded sizes (NPT/BSP), it ensures easy installation and reliable sealing, making it ideal for steam boilers, hot water boilers, and thermal fluid systems.

- Overview

- Recommended Products

- Check for leaks regularly.

- Clean exterior with mild detergent.

- If the valve becomes stiff, disassemble and lubricate with plumbing-grade lubricant.

- Avoid abrasive cleaners.

Product Overview

Core Features

Manual Radiator Valves are used to manually regulate the flow of hot water or steam into radiators in heating systems. These valves allow users to adjust the heat output of individual radiators, enhancing energy efficiency and comfort control in residential and commercial heating systems.

Manual Brass Boiler Relief Valve, Brass Boiler Safety Relief Valve, Threaded Boiler Pressure Relief Valve, 1/2" - 2" Boiler Relief Valve, Manual Brass Pressure Relief Valve

Specifications and Parameters:

| Product name | Brass Relief Valve | |

| Sizes | 1/2" - 2" | |

| Bore | Standard bore | |

| Application | Water, oil, and other non-corosive liquid | |

| Working pressure | PN10 / 150Psi | |

| Working temperature | -10 to 120°C | |

| Working durability | 10,000 cycles | |

| Quality standard | EN215 | |

| End Connection | BSP, NPT | |

| Features: | Forged valve body | |

| Anti-blow-out stem structure | ||

| 100% leakage test for each valve | ||

| OEM production acceptable | ||

| Materials | Spare Part | Material |

| Body | Forged brass, bronze-plated | |

| Bonnet | Forged brass, bronze-plated | |

| Spring | Stainless Steel 304 | |

| Handle | Steel | |

| Nut | Steel | |

| Stem | Brass | |

| Seat | NBR | |

| Packing | Bag for each piece, inner boxes in cartons, loaded in pallets | |

| Customized design acceptable | ||

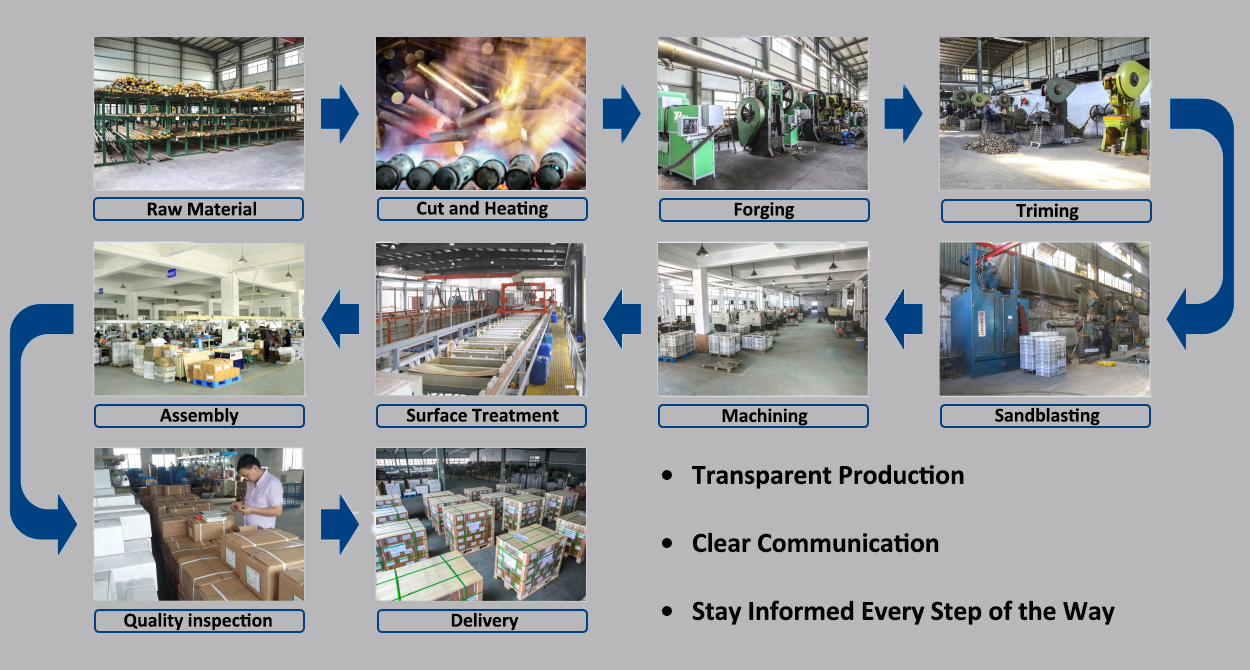

1.Production flow of Brass Radiator Valves:

2. Brass material Chemical composition used for brass radiator valves:

| European Market | Cu% | AL% | As% | Fe% | Mn% | Ni% | Pb% | Sn% | Zn% | Rest% |

| CuZn39Pb3(CW614N)MS58 | 57-59 | <0.05 | / | <0.3 | / | <0.3 | 2.5-3.5 | <0.3 | Rem. | <0.2 |

| CuZn40Pb2(CW617N)MS58-1 | 57-59 | <0.05 | / | <0.3 | / | <0.3 | 1.6-2.5 | <0.3 | Rem. | <0.2 |

| CuZn36Pb2AS(CW602N)DZR | 61-63 | <0.05 | 0.02-0.15 | <0.1 | <0.1 | <0.3 | 1.7-2.8 | <0.1 | Rem. | <0.2 |

| USA Market | Cu% | AL% | Ar% | Fe% | Pb% | Zn% | Rest% | |||

| C36000 | 60-63 | / | / | 0.35 | 2.5-3.7 | Rem. | ||||

| C37000 | 58-61 | / | / | 0.3 | 1.5-2.5 | Rem. | ||||

| C46500 Lead-free | 59-62 | / | / | <0.1 | <0.2 | 0.50-1.0 | Rem. | |||

| China National | Cu% | AL% | Ni% | Fe% | Sb% | Bi% | Pb% | P% | Zn% | Rest% |

| HPb59-1 | 57-60 | <0.2 | <1.0 | <0.5 | <0.01 | <0.003 | 0.8-1.9 | <0.02 | Rem. | <1.0 |

| HPb59-3 | 57.5-59.5 | / | <0.5 | <0.5 | 2.0-3.0 | Rem. | <1.2 | |||

| HPb57-3 (Normal Brass) | 57.0-59.0 | / | / | <0.8 | / | 1.7-3.0 | Rem. | ≤1.8 |

3. Bore sizes for brass radiator valves:

| 1/2" | 3/4" | 1" | 1 1/4" | 1 1/2" | 2" | 2 1/2" | 3" | 4" | |

| Full Bore | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| Standard Bore | 13.5 | 18 | 23 | 30 | 37 | 47 | 62 | 75 | 95 |

| Reduced Bore | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 |

4. Available surface treatments of brass radiator valves:

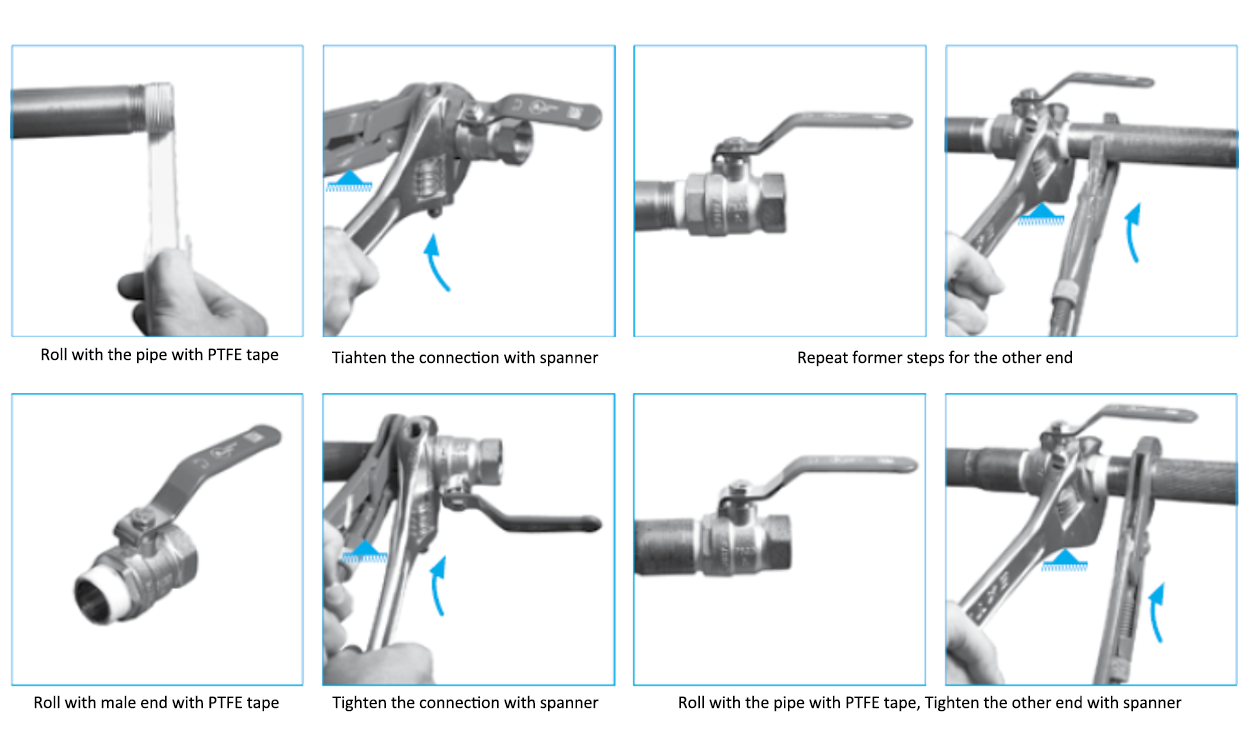

5. Installation instruction of brass radiator valves:

6. Packing of brass radiator valves:

Standard export packing, inner boxes in cartons, loaded in pallets.

Custom packaging is available.

7. Testing Lab for brass radiator valves:

Our testing laboratories are equipped with state-of-the-art equipment to ensure rigorous quality control at every stage of production. From product development to sample evaluation and full-scale production, we adhere to strict testing protocols as a fundamental part of our quality system, ensuring that every process meets the relevant standards.

8. Why choose BOTE as your China Brass Radiator Valve Supplier?

| 1 | Professional fluid solution provider, with over 18 years of industry experiences |

| 2 | Monthly production capacity of 1million sets, enables quick delivery with lower costs |

| 3 | Quality-oriented production process, test each valve during production |

| 4 | Intensive QC and on-time delivery, to make quality reliable and stable |

| 5 | Prompt responsive communications, from pre-sales to after-sales |

| 6 | We provide OEM/ODM services with flexible design and branding options |

| 7 | Our valves meet CE and ISO standards, ensuring global compliance |

Frequently Asked Questions (FAQ)

Q: What is the lead time for a custom order?

A: 3–6 weeks, depending on customization (e.g. port size, pressure rating, coating) and order volume. Standard models usually ship within 1–2 weeks.

Q: Are these valves suitable for hot water systems?

A: Yes. Operating temperature: -10°C to 120°C (14°F to 248°F). For temperatures above 120°C, please choose our high-temperature models.

Q: Are there color or finish options?

A: Standard finish is natural brass. Optional coatings include chrome plating (silver appearance) and custom organic coatings for added corrosion protection or design match.

Q: How should I maintain the valve?

A:

Q: Can it be used with water-based chemicals?

A: Yes, for mild water-based chemicals within rated limits. For harsh or concentrated chemicals, consult our technical team for suitable materials/coatings.

Q: Do you provide installation instructions?

A: Yes. Each valve includes detailed instructions. Online videos and technical support are also available.

Q: What is your after-sales policy for defective products?

A: We offer a warranty for manufacturing defects. If you receive any faulty valves, please contact us within 7 days of delivery with photos or videos of the issue. We will provide replacement parts, full replacements, or a credit/refund based on the situation. Our team is committed to prompt and reliable after-sales support.

Contact Us:

Ready to enhance your plumbing system with our Brass Ball Valves? Contact us today for a consultation and quote. Our team is here to help you select the right valve for your needs.

Email: [email protected]

Phone: +86 18968473237

Experience the difference that our high - quality Brass Ball Valves can make in your plumbing and fluid control applications – where reliability meets performance.