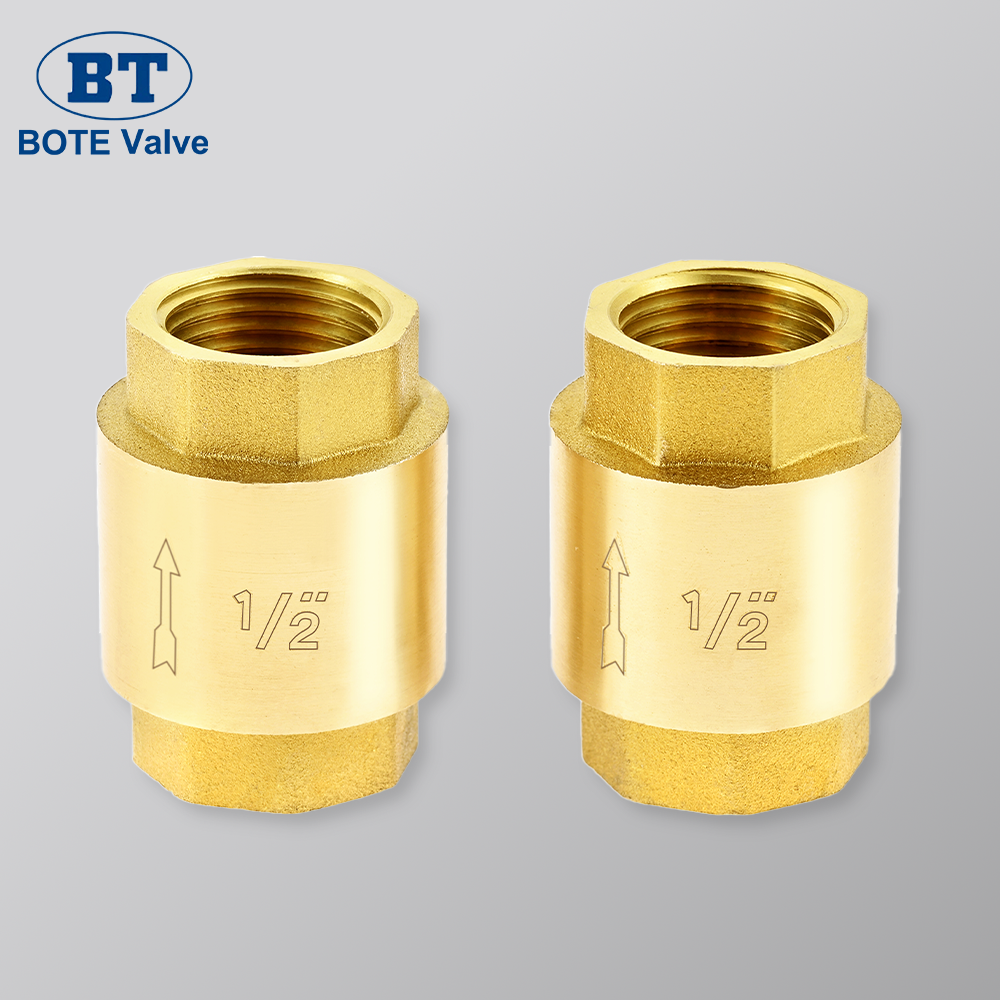

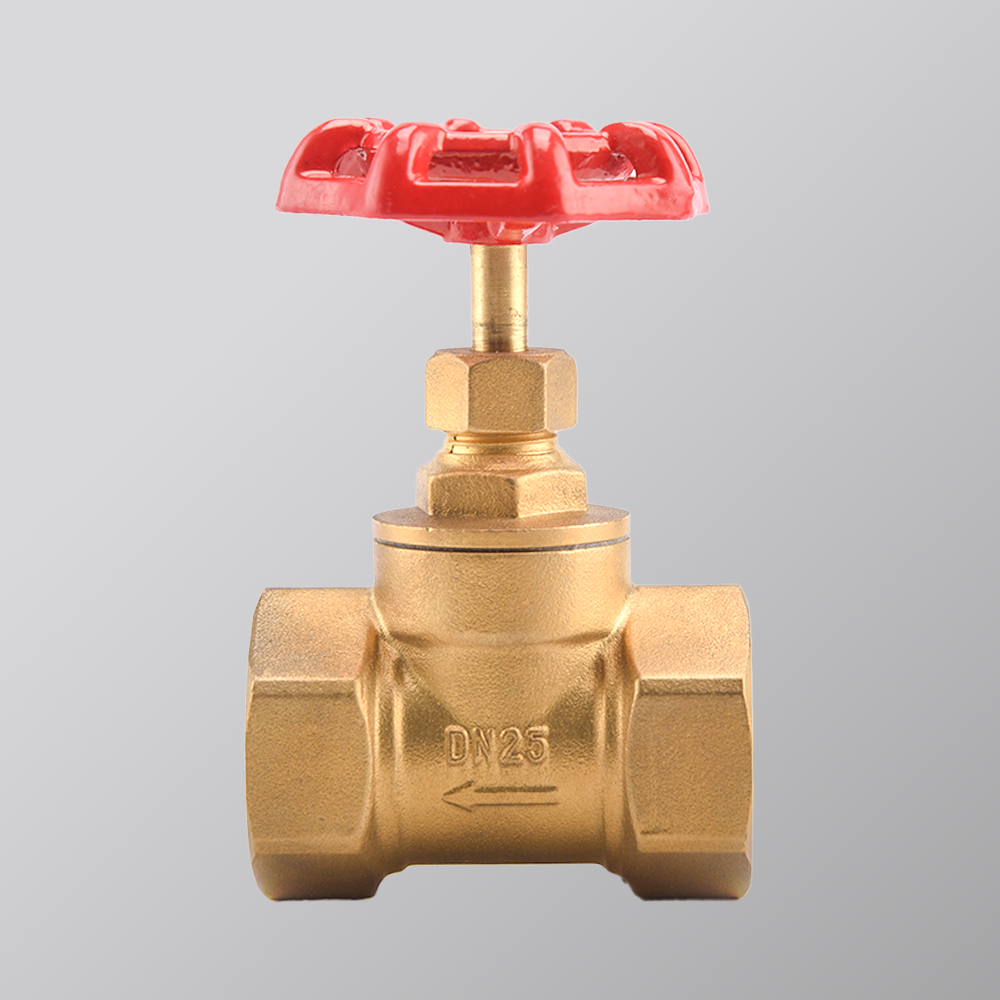

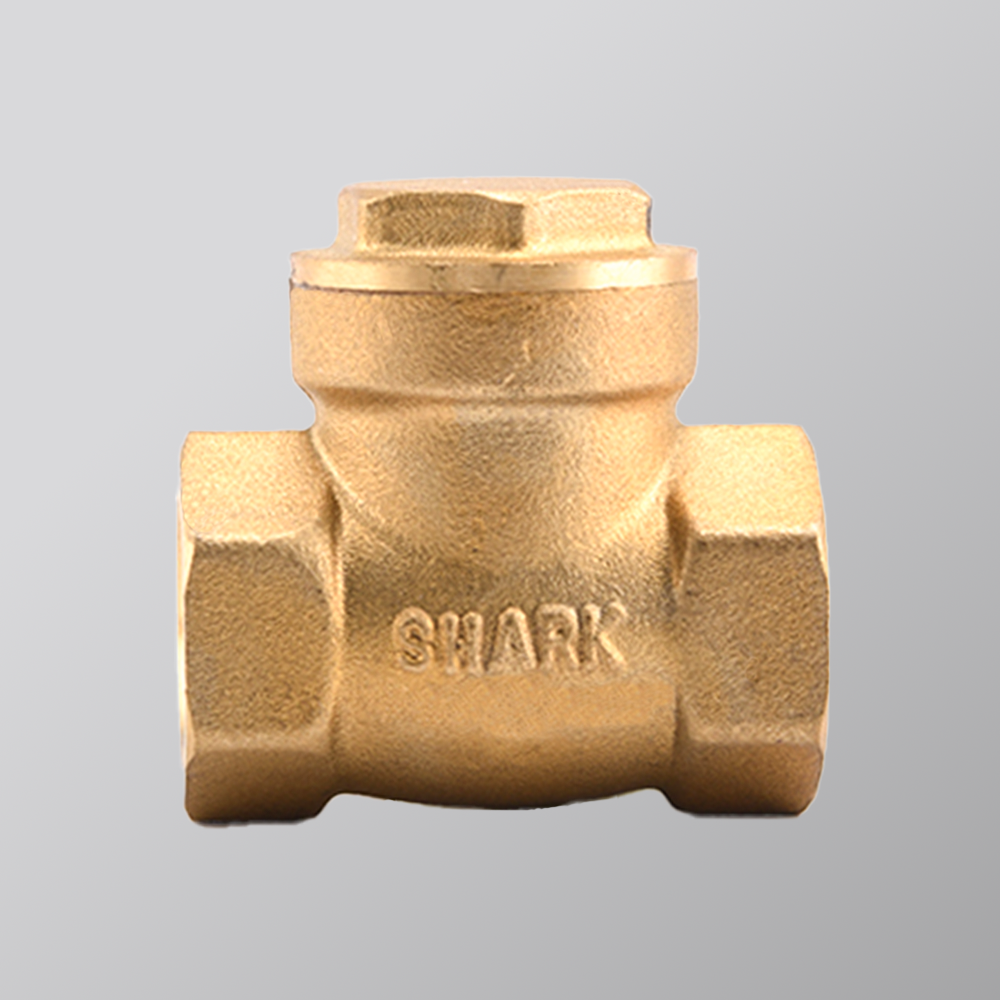

Brass Spring Vertical Check Valve - 1/2" to 2" Female Thread Non-Return Valve

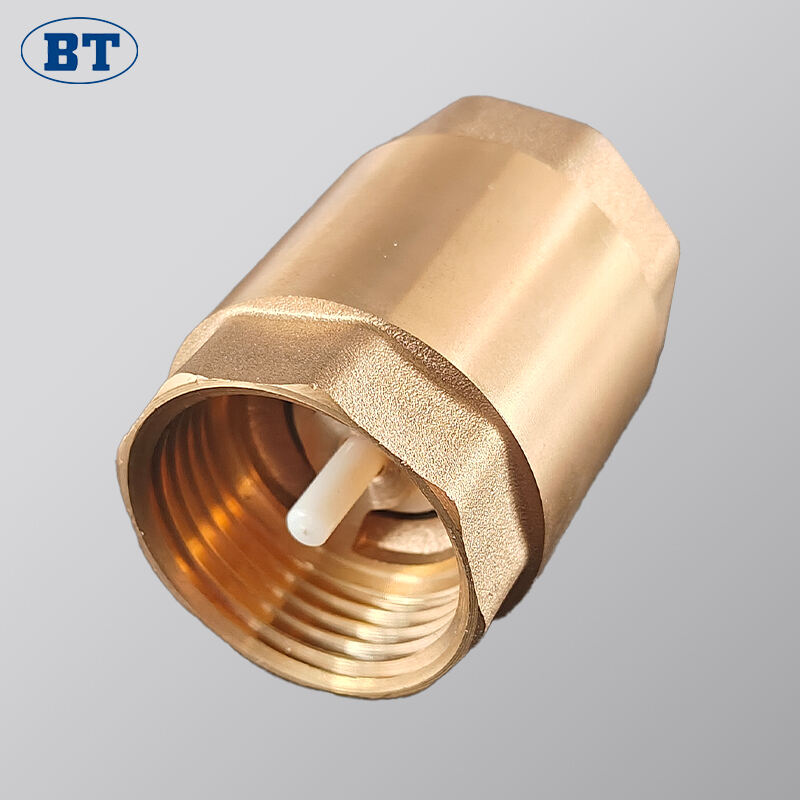

This brass vertical check valve (also known as a non-return valve) prevents media backflow in pipelines using self-actuating valve discs. Crafted from high-quality forged brass, it offers exceptional corrosion resistance and is ideal for water, oil, gas, and light industrial fluid systems. Available in sizes 1/2" to 2" with female NPT/BSP threads, it ensures easy installation and reliable sealing in both vertical and horizontal piping.

- Overview

- Recommended Products

- Check for leaks regularly.

- Clean exterior with mild detergent.

- If the valve becomes stiff, disassemble and lubricate with plumbing-grade lubricant.

- Avoid abrasive cleaners.

Product Overview

Core Features

Brass Vertical Check Valve, Female Thread Non-Return Valve, Forged Brass Check Valve, 1/2" - 2" Brass Valve, Corrosion-Resistant Check Valve

Specifications and Parameters:

| Product name | Brass Spring Check Valve, with brass disc | |

| Sizes | 1/2" ~ 4" | |

| Bore | Standard bore | |

| Application | Water, oil, and other non-corosive liquid | |

| Working pressure | PN16 / 200Psi | |

| Working temperature | -10 to 120°C | |

| Working durability | 10,000 cycles | |

| Quality standard | EN228-1 | |

| End Connection | BSP, NPT | |

| Features: | Heavy-duty design for higher pressure | |

| Anti-blow-out stem structure | ||

| 100% leakage test for each valve | ||

| OEM production acceptable | ||

| Materials | Spare Part | Material |

| Body | Forged brass, sandblasted and rough colour | |

| Bonnet | Forged brass, sandblasted and rough colour | |

| Disc | Brass | |

| Seat | NBR or EPDM | |

| Nut | N/A | |

| Stem | N/A | |

| Screw | N/A | |

| Packing | Bag for each piece, inner boxes in cartons, loaded in pallets | |

| Customized design acceptable | ||

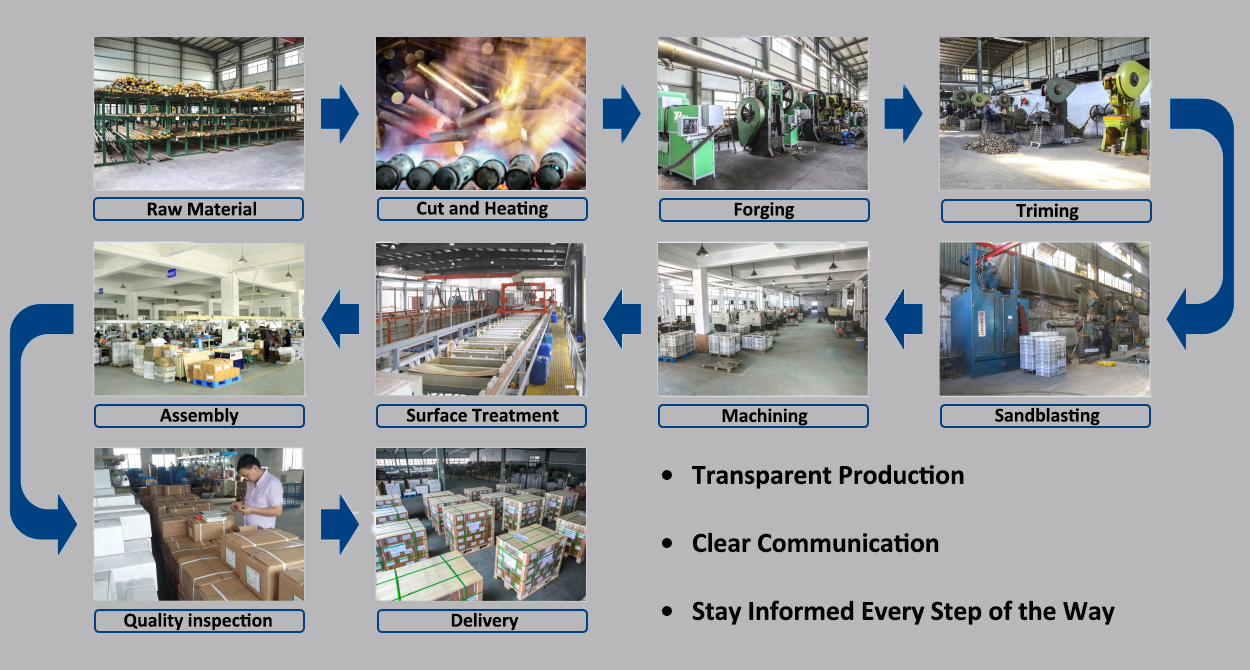

1.Production flow of Brass Check Valves:

2. Brass material Chemical composition used for brass check valves:

| European Market | Cu% | AL% | As% | Fe% | Mn% | Ni% | Pb% | Sn% | Zn% | Rest% |

| CuZn39Pb3(CW614N)MS58 | 57-59 | <0.05 | / | <0.3 | / | <0.3 | 2.5-3.5 | <0.3 | Rem. | <0.2 |

| CuZn40Pb2(CW617N)MS58-1 | 57-59 | <0.05 | / | <0.3 | / | <0.3 | 1.6-2.5 | <0.3 | Rem. | <0.2 |

| CuZn36Pb2AS(CW602N)DZR | 61-63 | <0.05 | 0.02-0.15 | <0.1 | <0.1 | <0.3 | 1.7-2.8 | <0.1 | Rem. | <0.2 |

| USA Market | Cu% | AL% | Ar% | Fe% | Pb% | Zn% | Rest% | |||

| C36000 | 60-63 | / | / | 0.35 | 2.5-3.7 | Rem. | ||||

| C37000 | 58-61 | / | / | 0.3 | 1.5-2.5 | Rem. | ||||

| C46500 Lead-free | 59-62 | / | / | <0.1 | <0.2 | 0.50-1.0 | Rem. | |||

| China National | Cu% | AL% | Ni% | Fe% | Sb% | Bi% | Pb% | P% | Zn% | Rest% |

| HPb59-1 | 57-60 | <0.2 | <1.0 | <0.5 | <0.01 | <0.003 | 0.8-1.9 | <0.02 | Rem. | <1.0 |

| HPb59-3 | 57.5-59.5 | / | <0.5 | <0.5 | 2.0-3.0 | Rem. | <1.2 | |||

| HPb57-3 (Normal Brass) | 57.0-59.0 | / | / | <0.8 | / | 1.7-3.0 | Rem. | ≤1.8 |

3. Bore sizes for brass check valves:

| 1/2" | 3/4" | 1" | 1 1/4" | 1 1/2" | 2" | 2 1/2" | 3" | 4" | |

| Full Bore | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| Standard Bore | 13.5 | 18 | 23 | 30 | 37 | 47 | 62 | 75 | 95 |

| Reduced Bore | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 |

4. Available surface treatments of brass check valves:

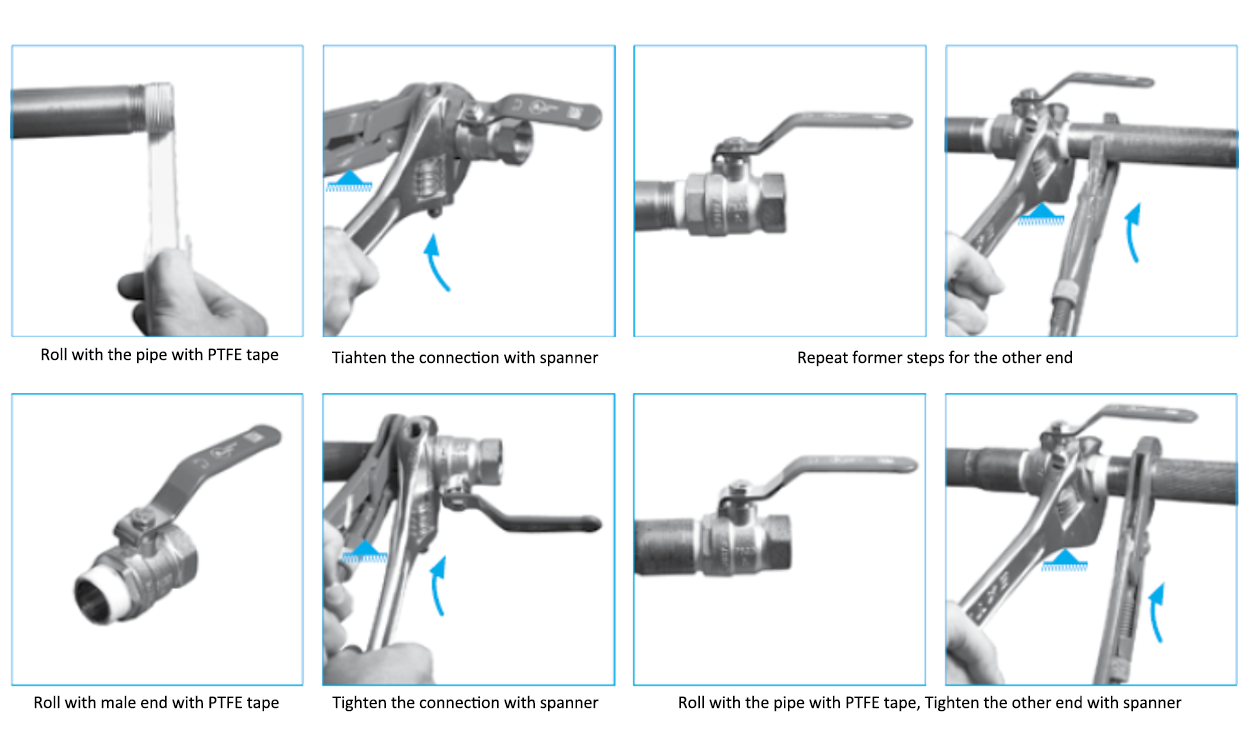

5. Installation instruction of brass check valves:

6. Packing of brass check valves:

Standard export packing, inner boxes in cartons, loaded in pallets.

Custom packaging is available.

7. Testing Lab for brass check valves:

Our testing laboratories are equipped with state-of-the-art equipment to ensure rigorous quality control at every stage of production. From product development to sample evaluation and full-scale production, we adhere to strict testing protocols as a fundamental part of our quality system, ensuring that every process meets the relevant standards.

8. Why choose BOTE as your China Brass Check Valve Supplier?

| 1 | Professional fluid solution provider, with over 18 years of industry experiences |

| 2 | Monthly production capacity of 1million sets, enables quick delivery with lower costs |

| 3 | Quality-oriented production process, test each valve during production |

| 4 | Intensive QC and on-time delivery, to make quality reliable and stable |

| 5 | Prompt responsive communications, from pre-sales to after-sales |

| 6 | We provide OEM/ODM services with flexible design and branding options |

| 7 | Our valves meet CE and ISO standards, ensuring global compliance |

Frequently Asked Questions (FAQ)

Q: What is the lead time for a custom order?

A: 3–6 weeks, depending on customization (e.g. port size, pressure rating, coating) and order volume. Standard models usually ship within 1–2 weeks.

Q: Are these valves suitable for hot water systems?

A: Yes. Operating temperature: -10°C to 120°C (14°F to 248°F). For temperatures above 120°C, please choose our high-temperature models.

Q: Are there color or finish options?

A: Standard finish is natural brass. Optional coatings include chrome plating (silver appearance) and custom organic coatings for added corrosion protection or design match.

Q: How should I maintain the valve?

A:

Q: Can it be used with water-based chemicals?

A: Yes, for mild water-based chemicals within rated limits. For harsh or concentrated chemicals, consult our technical team for suitable materials/coatings.

Q: Do you provide installation instructions?

A: Yes. Each valve includes detailed instructions. Online videos and technical support are also available.

Q: What is your after-sales policy for defective products?

A: We offer a warranty for manufacturing defects. If you receive any faulty valves, please contact us within 7 days of delivery with photos or videos of the issue. We will provide replacement parts, full replacements, or a credit/refund based on the situation. Our team is committed to prompt and reliable after-sales support.

Contact Us:

Ready to enhance your plumbing system with our Brass Ball Valves? Contact us today for a consultation and quote. Our team is here to help you select the right valve for your needs.

Email: [email protected]

Phone: +86 18968473237

Experience the difference that our high - quality Brass Ball Valves can make in your plumbing and fluid control applications – where reliability meets performance.