በአገር ውስድ የሚጠቀመውን ውሃ ከ20% ያህል የማይ ማሽኖች ይወስዳሉ በEPA ከ2023 የታወቀ, ነገር ግን ሰዎች ያሉትን አደጋዎች ስለ ማያቶቹ በአንጻራዊነት አያስቡም። የኢንሹራንስ ድርጅቶች ከየትኛውም ቤተ መንግስት በየዓመቱ ስለ 2% ውሃ ጥቃት እንዳለ ሲገኙ የማይ ማሽን ላይ ያሉ ቫልቮች ከሥራ የሚውሩ ምክንያት ነው። እነዚህ ትንሽ ቫልቮች ከፍተኛ አስፈላጊነት አላቸው ምክንያቱም ነገር ቢሳካ ውሃ ከማፈሰስ ያቆማሉ፣ ከቤቱ ውስጥ የሚተላለፍ አደጋ ከመጀመሪያው ቦታ የሚቆመው ስለሆነ ነው።

ከፍተኛው የቤት ውስጥ ውሃ ጥፋት ከሶስት የቧንቧ ነጥቦች የሚመጣ ነው፡ የቆረቆሪያ መገጣጠሚያዎች ሲበላሽ (34%)፣ የቬልቪ አካል መበላሸት (28%)፣ እና በዘፈቀደ የኩብ መዛባት (22%)። ሁሉንም ቤት ውሃ ለማቋረጥ የሚያስፈልጉ ዋና የመዝጊያ ቬልቪዎችን በተቃራኒ፣ የአንግል ቫልቮች የተወሰኑ ማይዶዎችን ይከፍላሉ በመርከቢያ ወይም በአደገኛ ሁኔታ ውስጥ የማሽን ማጽጃ አቅራቢ መስመሮች ላይ።

የ90 ዲግሪ የአንግል ቫልቭ ዲዛይን የኮምፕሬሽን ወይም የተዘረዘሩ ግንኙነቶችን በመጠቀም የውሃ ማስከለል ያсоздает። ከተዘጉ በኋላ፣ የሴራሚክ ዳይስ ካርትሪጅ የውሃ ፍሰት ሙሉ በሙሉ ይቆጣጠራል፣ ከዚያ የአራት ግዞች ክዋኔ የፍሳሽ ምንጮችን በፍጥነት ለመመለስ ያስችላል—ይህ በባድ የውሃ ጥፋት ከፍተኛ የሆነ ከፍተኛ የኢንሹራንስ ዋስትና $12,514 በአን الواحد ዕዳ (IICRC 2023)።

በ-2023 ዓ.ም. 12,000 የሆነ የጠየቅ ትንተና የማሽን ማጽጃ ጋር የተያያዘውን የውሃ ጥፋት ከ7 ዓመት በላይ ያገገመውን መቆሚያ ሲመለከት 70% ነው። የብረት ማዕቀፍ መቆሚያዎች ያላቸው ባለቤቶች የሚፈስ ውሃ በ plastic የተሰሩትን በማነሳሳት 40% ያነሰ ነበር፣ ይህም ረጅሙ ጊዜ የሚቆይ የመከላከል ስራ ላይ ዘላቂ ግንባታ አካላት እንዴት እንደሚሆኑ ያሳያል።

በቤት ውስጥ ያሉ የplumbing ስርዓቶች ውስጥ የIoT አዋቂነት ምክንያት አሁን የумный angle valves የራሳቸውን የመተላለፊያ መመርመሪያ ጋር በጠቅላላ የአዲስ አስገባሾች 18% ይሸፍናሉ። እነዚህ መሣሪያዎች በአномالي ሲገኙ ውስጥ 15 ሰከንድ ውስጥ የውሃ ፍሰት ሊያቃጥሉ ይችላሉ፣ እና የሚከሰተውን 94% የ flood ሁኔታዎች ሊከላከሉ ይችላሉ (Smart Home Water Solutions Report 2024)።

የኢንዱስትሪ አመራሮች የሚከተሉትን የማዕቀፍ መቆሚያዎች ለመግለጽ ያስመክላሉ፡

ይህ የቴክኒካል ደረጃ አቀራረብ የመሣሪያ መቆሚያዎችን በማስተካከል የሚፈለገውን ጥገና በ 63% ያቀንሳል (የፕላምቢንግ ማምረቻ ዓለም አቀፍ ድርጅት፣ 2023)።

የማሽን ማጠፊያ ያለው ክፍል ምን ያህል ያስቆራል በተወሰነ ጊዜ ላይ ምን እንደተሰራ ላይ የተመሰረተ ነው። ብዙ ሰዎች በብረት የተሠሩ ክፍሎችን ይምረጥታሉ እኩል ያልሆነ ዋጋ እና ምቹ መከላከያ ስላቀርቡ፣ ብዙውን ጊዜ ከ 12 እስከ 15 ዓመታት ድረስ በአገር ውስጥ በመደበኛ ጥቅም ላይ ይቆያሉ። በ 2023 የተደረገው የፕላሚንግ እቃዎች ጥናት የባለ ማይክሮ ብረት ያላቸው ክፍሎች የእርጥበትን ተጽዕኖ በብዙ ጊዜ የበለጠ ይቋቋማሉ እና በፈተናዎቹ ውስጥ ከኮሮዴን ጋር በተያያዘ ከፍተኛ መከላከያ ያሳያሉ፣ ይህም ከባሕር ጋር ባለ ግንባታዎች ለሚገነቡበት አካባቢ ጥሩ ነው ምክንያቱም ጨው የሚያስከትለውን አየር ለመቋቋም ያስችላል። ፕላስቲክ ክፍሎች በቅርብ ጊዜ በጣም ተሻሽሎ እና እስከ 450 psi ግፊቶችን ሊይዙ ይችላሉ፣ ነገር ግን በሙያ የተገኘ ልምድ የሚያሳይው የፓላስቲክ ክፍሎች በመጀመሪያዎቹ ከ 5 ዓመታት ውስጥ የብረት ክፍሎች ሶስት ጊዜ የበለጠ ይወድዳሉ ማለት ነው።

| መተግበሪያ | የሚመከር ግንኙነት | ዋና ጥቅም | ገደብ |

|---|---|---|---|

| ላመድ ስርዓቶች | ብሌይ ያልሆነ ብረት | ዋጋ-አስተዋጽኦ ያለው የኮሮዥን መከላከያ | የአሲድ ውሃ ሊገድበው ይችላል |

| እርጥብ/ከፍተኛ ጨው ያላቸው አካባቢዎች | የ316 የማይዘገይ ብረት | የክሎራይድ ተቃውሞ | 40% የዋጋ ገደብ |

| የዋጋ ግምት ያላቸው ፕሮጀክቶች | የተጠንካረ ገጽታ | ቀላል አሰጣጥ | በአማካይ 5 ዓመት የሚቆይ ዕድሜ |

የፕላስቲክ ክፈፍ ባለው የግቤ ታንኮች አሁን በአሜሪካ የፒያዝ ሽያጭ 38% ይይዛሉ፣ ከዚያ ግን የሞገስ ጥራት የተረጋገጠ የመቆይ ኃይል ቢኖራቸውም። ይህ አዝማሚያ የቤት ባለቤቶች ረጅሙን ጊዜ የሚቆይ ጥራት ሲገርሱ ቀላል አሰጣጥን (የፕላስቲክ ግንኙነት ጊዜ 60% ፈጣን) ይመርጣሉ የሚለውን ነው። ሆኖም ግን፣ የኢንሹራንስ ዳታ የሚያሳይበት ግን የ7 ዓመት ወይን በታች የሚገኘው የፕላስቲክ ክፈፍ ባለው የማሽን ፍሳሽ ጉዳዮች 71% ይሆናል ትላል

የደረቃ ብረት ያለው ቫልቮች በ 85% ከሚታወቀው ንብረት ውስጥ በማይቆመው 1,000 ሰአቶች ውስጥ ምንም ምል ስላያሳዩ ከኩሬ ቫልቮች ጋር ሲነፃፀር አራት ጊዜ ይሻላሉ። ኩሬ ለእራሱ የተጠበቀ покрытие (የመከላከያ ሽፋን) ሊፈጥር ይችላል፣ ግን ፈተናዎች ውሃ በጣም አሲዳዊ ሆኖ ፖሃ (pH) በግምት በ 6.5 ባታን ሲገባ ይህ ሽፋን ሁልጊዜ ይሰርዛል ተብሎ አረጋግጠዋል። የቧንቧ ጉድለቶችን ለማስቀረት ከባሕር ጋር በቅርብ የሚኖሩ ወይም የተዘጋጀ ውሃ የሚጠቀሙ ቤተኛዎች በየዓመቱ ከሁለት መቶ በላይ የሚያስቆጡ ለማድረግ ከኩሬ የሚበልጡ በግምት $22 ያህል የሚጨርስ የደረቃ ብረት ያለው ቫልቮች ለመግዛት ሊያስቡ ይገባል።

የቤት ውሃ ሲስተሞች በአጠቃላይ በ 40–80 PSI መካከል ይሰራሉ፣ ነገር ግን የከተማ አቅርቦቶች በከፍተኛ ጥረት ጊዜ ላይ 100 PSI ሊያሳዩ ይችላሉ። ከ 125 PSI በላይ የሚገ법 የኩሽሮ ቫልቭ መምረጥ በጨመቀው ግፊት ስር ጥብቅ ልክ ለመስራት ያስችላል። የኢንዱስትሪ ጥናቶች የ 80 PSI በታች የሚገብ የቫልቮች መጠን በከፍተኛ ጭንቀት ያለባቸው አካባቢዎች ውስጥ በ 3 ጊዜ ፈጽሞ እንደሚሰሩ ያሳያሉ ( የፕላምኒግ ደረጃዎች የሪፖርት፣ 2023 ).

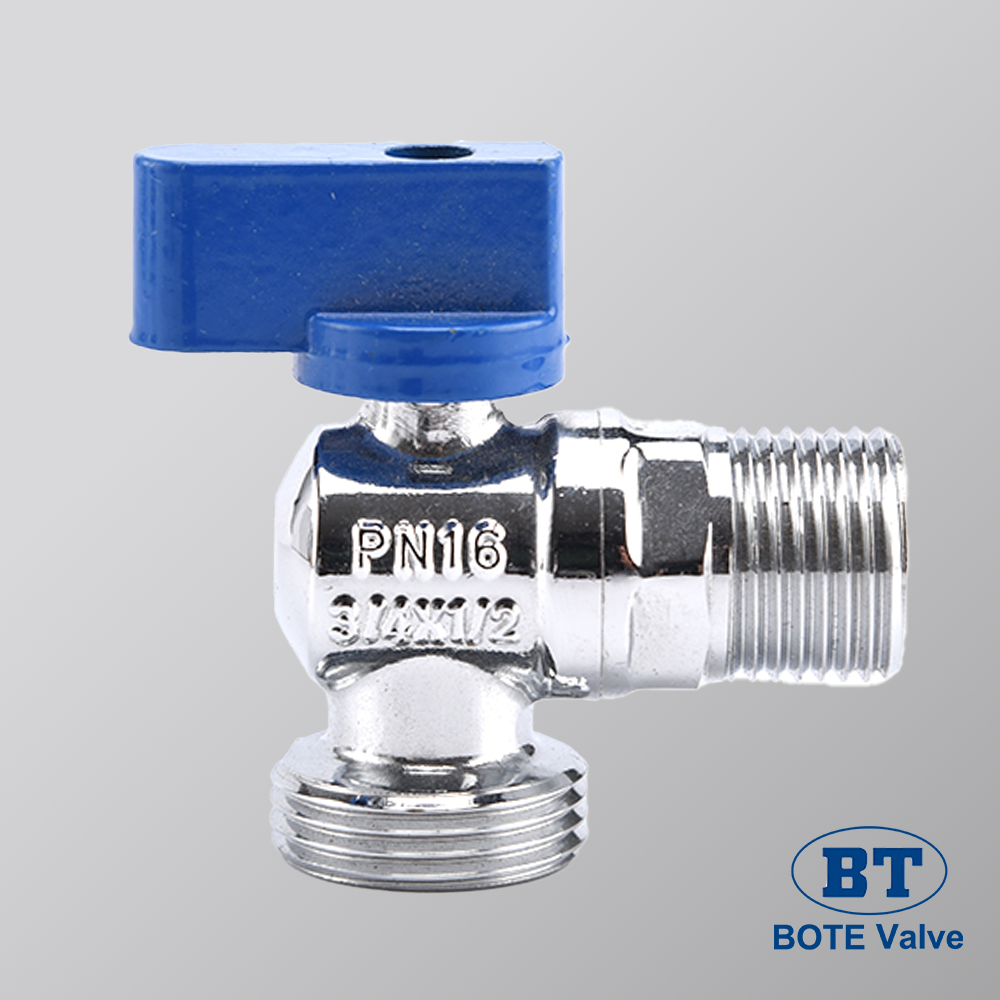

መደበኛ 1/2" ግቤት ግንኙነቶች ከአብዛኛው የቤት ውሃ አቅርቦት መስመሮች ጋር ይጣጣማሉ፣ የ 3/8" ውጤት ቦታዎች ደግሞ በቀላሉ ጋር የማሽን ማጽጃ ጉድጓዶችን ያጣጣማሉ። የተዛባ መጠን 38% የመጫን ጊዜ የሚከሰቱ ውሃ መፍሰስ ይፈጥራል፣ ምክንያቱም የሚያበልጥ ቫልቮች የጉድጓድ ႔ሪዶችን ያጫናሉ ሌላ ደግሞ ያንሳል ፍሰት ያገደዳል። ዘመናዊ ምርት የሚያመርቱ ኩባንያዎች የቆዳ ያልሆኑ 3/4" የፕላምቢንግ ስርዓቶችን ለማስተናገድ ሁለት ግንኙነቶች ያሉ መቀየሪያዎችን አሁን ያካትታሉ።

የአራት ክፍል ማስቆሚያ ቫልቮች የማይፈስ የሴራሚክ ዳርቻ መካኒዝሞች ስላቸው በዘመናዊ አሰጣጥ ውስጥ ይገለብጣሉ፣ እነዚህ ቫልቮች በተለዋዋጭ ግጭት ላይ ያሉ የድረስታ ሙከራዎች ውስጥ በማስቆሚያ መንገዶች ላይ ባሉ የግድግዳ ዲዛይኖች ከ92% ጋር ይቫስራሉ። ለቋሚ ግንኙነቶች የብረት ግንኙነቶች ከፈለጉ ይቀመጣሉ፣ የሚታዩ ግንኙነቶች ደግሞ በዲአይ와ይ ሁኔታዎች ውስጥ የሚፈስ ድንገት ከ60% ጋር ይቀንሳል፣ ይህም የተዋሃደ የሩቢር መዝጊያዎችን እና የበረዶ ብረት ምolars ይጠቀማል።

የማዕዘን ቫልቮች ለማጽጃ መኪናዎች ጠቃሚ ናቸው ምክንያቱም ውሃ ፍሰት ሲቆም ውሃ ጉድለት ሲፈጠር ለመከላከል የተወሰነ የውሃ ፍሰት ማስቆሚያ ይሰጣሉ።

ለሙቀት የተሞላ አካባቢዎች የበረዶ ብረት የተመረጠ ምክንያቱ በረዶ ከሌለው ብረት ጋር ሲነፃፀር የተሻለ የመበላሸት ችሎታ አለው፣ ስለዚህ እንደ ቡረት ያሉ ግንኙነቶች በእንዲህ ዓይነት ሁኔታዎች ውስጥ ሊበላሽ ይችላሉ።

ራዲያተር ማጥፊያ ባለው የመሳሪያ መቆሚያዎች በማታ ላይ ሲፈስ ሕንፃውን ማጥፍ እንዲቻል ያደርጋል፣ በተለይ የቤት ባለቤቶች ሲሄዱ ግድን ለመከላከል ይረዳል፣ ስለዚህ የውሃ ጥፋት ሲፈሰስ ትልቅ ጉዳት ሳይፈጥር ያስቀምጣል።

የፕላስቲክ ማጥፊያ ባለው መሳሪያ መቆሚያዎች ለመጫን ቀላል ሆነባቸው ረጅሙን ጊዜ ግን ያነሰ ጥራት አላቸው፣ ከብረርሳ እና ከአይዝ ብረት ጋር ሲነፃፀር የበለጠ ስርዓተ ምግባር አላቸው፣ ስለዚህ የውሃ ጥፋት ሲከላከል ያነሰ ተስማሚነት አላቸው።

የብረርሳ ማጥፊያ ባለው መሳሪያ መቆሚያዎች በተለምዶ በተለመደ የቤት ጥገኝነት ሁኔታዎች ስር 12 ከ 15 ዓመታት ያስቆጣሉ።

በተደጋጋሚ ሣ📐 nieu

በተደጋጋሚ ሣ📐 nieu