Angle valves for toilets serve as critical control points in residential plumbing systems, enabling localized water flow management while preventing leaks. By allowing precise shut-off access directly at the fixture, these valves minimize risks of water damage and simplify maintenance tasks.

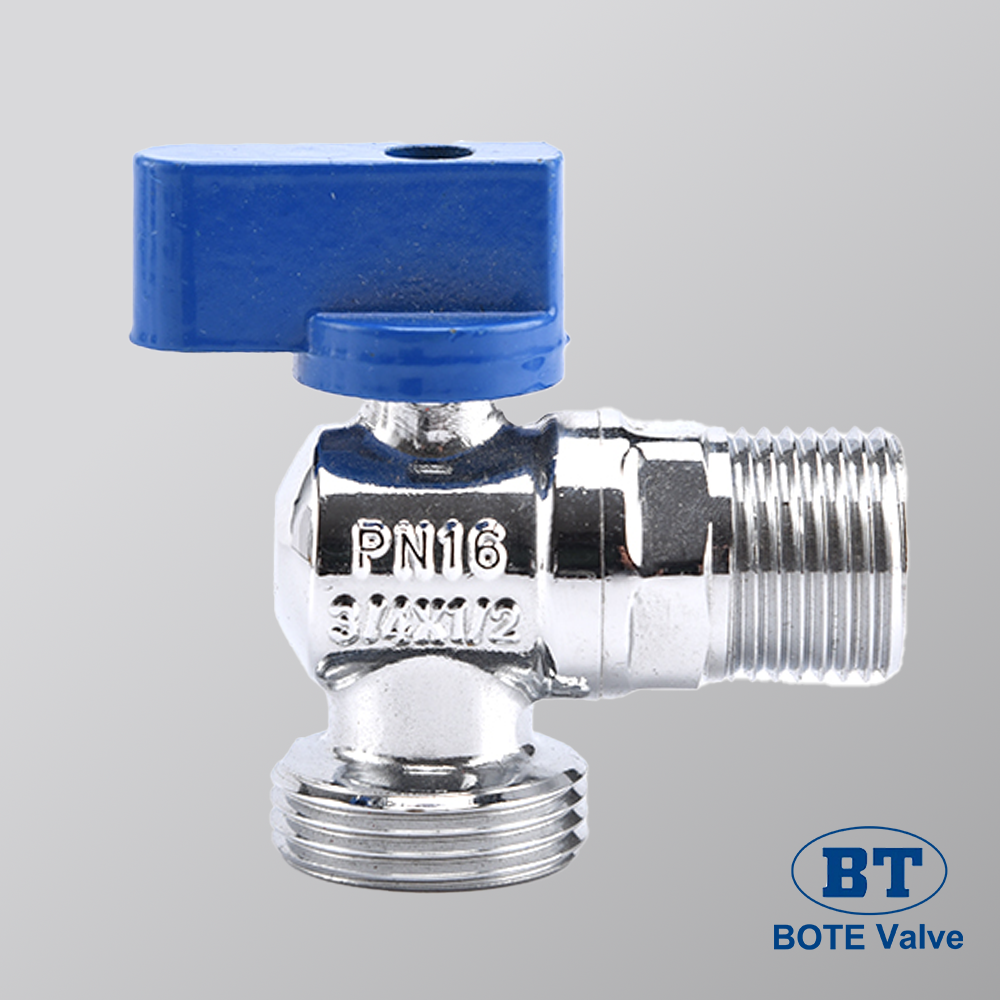

Angle stop valves serve as those handy middlemen connecting main water lines to bathroom sinks, kitchen faucets, and similar fixtures around the house. The 90 degree bend in these valves isn't just for show either it actually saves precious inches in cramped wall spaces behind vanities and under sinks, all while still giving plumbers good control when they need to cut off water flow. According to some recent plumbing research, homes with correctly installed angle stop valves see about a two thirds drop in emergency leaks versus houses that only depend on turning off the main water valve during repairs. This means plumbers can fix problems at one location without leaving the rest of the house without running water, which makes everyone's day a whole lot better.

Good quality toilet angle valves stop those disastrous leaks mainly because they have two important parts working together. First there are these compression sealed stems which don't wear out as fast, and second comes the quarter turn ball valve design that actually stops water flow completely when needed. Looking at what plumbers see during emergency repairs tells us something pretty shocking really. About 92 percent of all water damage problems related to toilets happen where people either didn't install angle valves at all or got cheap ones that failed over time. For anyone serious about preventing water disasters, look for models with this dual seal tech. These valves block leak paths from inside and outside the fixture itself, giving homeowners much better protection against unexpected bursts and drips that can cause so much damage if left unchecked.

Their compact design makes them ideal for confined spaces behind toilets while maintaining easy access for maintenance. Properly sized angle valves ensure consistent water pressure to fill valves without stressing connection points.

Most home plumbing setups rely on either 1/2 inch or 3/8 inch angle valves when installing toilets. The bigger 1/2 inch valve with about 14.3 mm inside space usually hooks up to regular water supply lines found in newer houses. Smaller 3/8 inch models measuring around 10.5 mm tend to connect bathroom faucets to those little shut off valves we all know. Getting the wrong size creates problems down the line. If the valve is too small, water pressure drops dramatically sometimes as much as 40% according to Plumbing Standards Institute research from 2022. On the flip side, going too big increases chances of leaks where threads meet because it doesn't seal properly. Before buying anything, grab some calipers and actually measure what's already there. What looks like 1/2 inch on the outside might be different inside since metal walls vary in thickness between manufacturers.

Modern toilets require 7/8-inch to 1-1/4-inch clearance between the valve body and wall for proper installation. Check these three compatibility factors:

Non-adjustable 1/2-inch valves fail in 23% of installations where supply lines have metric threading (European Plumbing Journal 2023). Use flexible braided supply lines with swivel nuts if wall outlets aren’t perfectly aligned.

Older homes often mix imperial and metric plumbing components—15 mm European pipes (0.59 inches) frequently conflict with standard 1/2-inch (0.625-inch) valves. For mixed systems:

In multi-unit buildings with older infrastructure, high-rise applications may require more robust valves or pressure regulators. To enhance compatibility:

When it comes to choosing angle valves for toilets, material selection plays a crucial role. Let's take a look at common materials and their respective benefits.

| Material | Durability | Corrosion Resistance | Cost |

|---|---|---|---|

| Brass | High | Excellent | Higher |

| Stainless Steel | Very High | Excellent | Higher |

| Plastic | Moderate | Moderate to Low | Low |

The features below are crucial in determining the reliability and longevity of an angle valve for a toilet:

According to studies:

Investment in durable materials and precise fittings pays dividends by significantly lowering the frequency of repairs and the likelihood of future leaks.

Quarter-turn valves are renowned for their efficiency and longer durability due to their simple operation involving only a 90-degree turn of the handle, as opposed to multiple full rotations required by multi-turn valves. Multi-turn valves, on the other hand, are composed of parts that are more prone to wear due to friction. Therefore, quarter-turn valves are typically preferred for their durability and ease of use in residential plumbing systems.

A key feature of ball valves is their ability to drastically minimize internal leaks and wear, as they provide a full bore design that reduces water flow restriction. The precision-machined mechanical seals in ball valves prevent mineral buildup that can lead to leaks, a common problem in traditional valves that use compression seals.

| Seal Type | Compression Valve | Ball Valve | Push-Fit Valve |

|---|---|---|---|

| Leak Resistance | Moderate | High | Moderate to Low |

| Durability | Moderate | Very High | Moderate |

| Installation Requirements | Moderate effort, requires tools | Less effort, requires tools | Minimal effort, no tools needed |

Selecting the right type and size of valve is crucial for avoiding unnecessary maintenance and ensuring long-term functionality. Compression valves require regular maintenance, while ball valves offer a more hands-off experience with higher performance and reliability.